PTI's SCADA and Automation Solutions: Empowering Industries with Vast Process Knowledge

Ignition SCADA by Inductive Automation®: The New SCADA for Streamlined Automation

Discover the power of Ignition SCADA by Inductive Automation®, the ultimate solution for supervisory control and data acquisition (SCADA). PT Industrial Electric Co. Ltd (PTI) leverages industry-leading Ignition and Inductive Automation technologies to drive automation excellence across industries. Our skilled team deploys these advanced platforms, seamlessly complementing SCADA and PLC systems, to optimize processes and enhance overall operational efficiency. With PTI's tailored solutions, industries experience heightened productivity, reduced downtime, and enriched data visualization, securing a competitive edge in today's dynamic market.

Advantages of Embracing Ignition SCADA by Inductive Automation

• Unlimited Licensing: Embrace a cost-effective approach with unlimited tags, clients, screens, and connections.

• Web-Based Deployment: Effortlessly launch web clients on any device with a web-browser for flexible accessibility.

• Universal Platform: Consolidate SCADA, alarming, reporting, and more onto one scalable platform.

• Rapid Development: Empower your team with a powerful, unlimited, zero-install Integrated Development Environment (IDE) for accelerated project execution.

• Built on Trusted IT Standards: Rely on industry-standard technologies like SQL, Python, MQTT, and OPC UA.

• Industry-Leading Support: Access top-notch tech support and comprehensive training for seamless implementation.

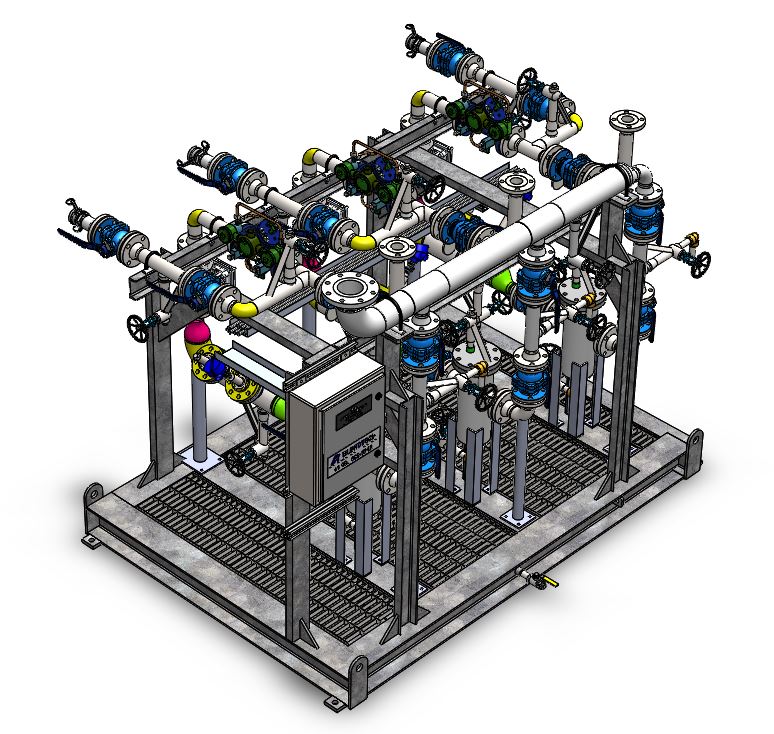

Enhanced Data Acquisition with Ignition SCADA Software

Ignition SCADA software comes standard with an extensive set of data acquisition tools. It incorporates built-in OPC UA for connectivity to virtually any PLC and offers seamless integration with any SQL database. Additionally, Ignition can transform any SQL database into a high-performance industrial historian and easily connect to IIoT devices through MQTT.

Unleashing the Power of Ignition's Designer

Ignition's Designer, the industry's most powerful IDE, propels rapid development for your project. Designed within the platform, the Ignition Designer is instantly accessible, version-friendly, and compatible with major OS, ensuring unlimited concurrent design clients. PTI empowers your entire team to collaborate simultaneously from any location, enhancing efficiency without additional costs.

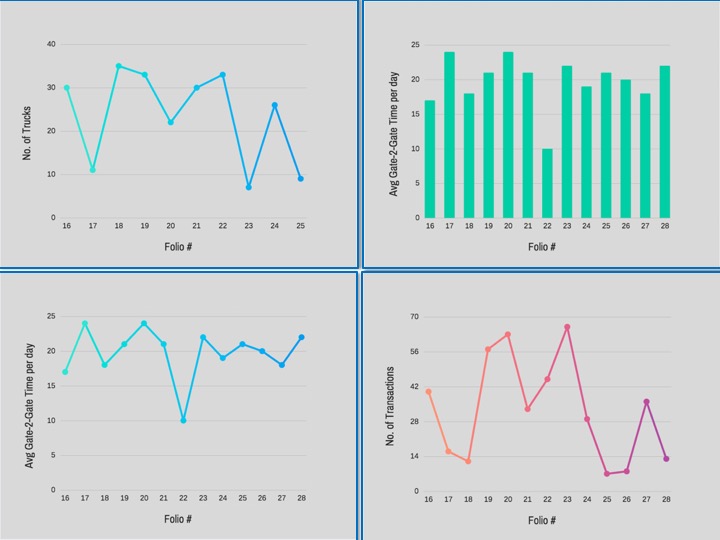

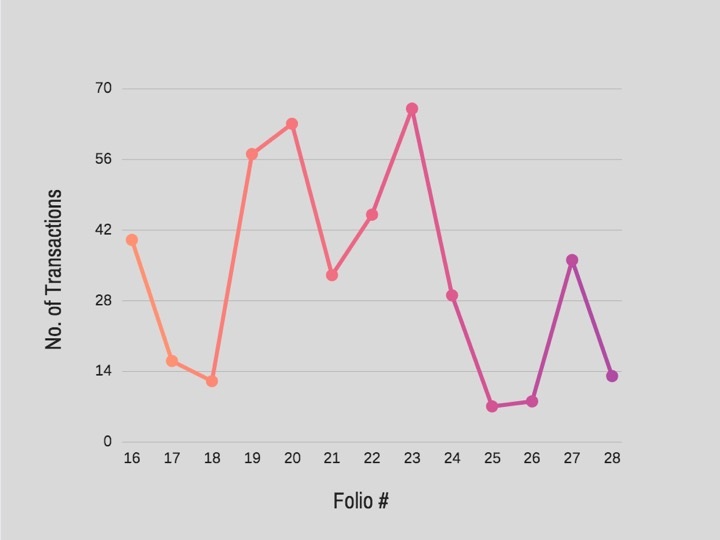

Real-Time Monitoring for Informed Decision-Making

Ignition's streamlined data-throughput provides true real-time tag values. The real-time monitoring capability empowers quick assessment of facility status on any device, empowering informed decision-making and responsive actions.

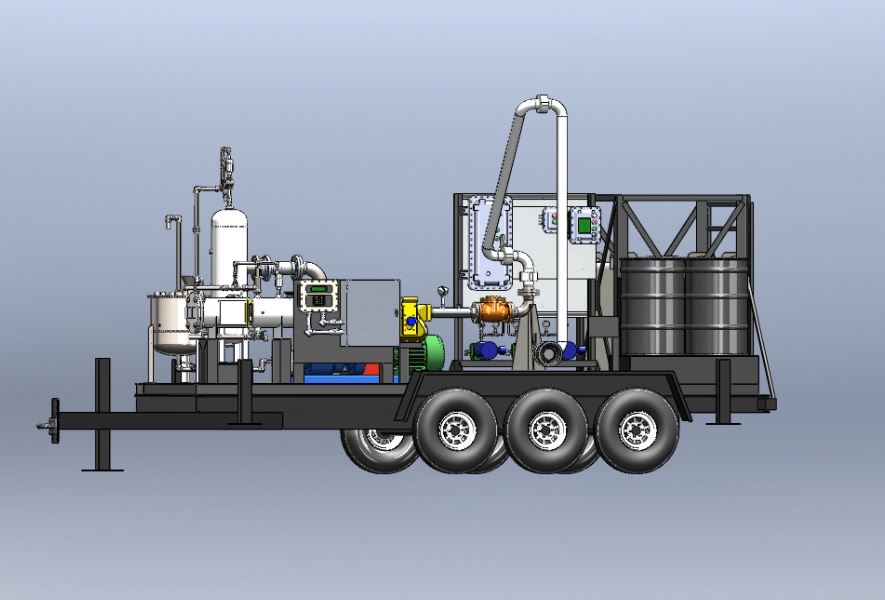

Powerful HMI solutions for Process Control

PTI's HMI solutions equip you with the capability to start and stop processes, monitor multiple data points across locations, and monitor the entire plant floor status in real-time. With the Ignition Designer, effortlessly craft optimized HMI screens tailored to your specific requirements.

Empowering Dynamic SCADA Dashboards

Ignition facilitates easy creation of dynamic SCADA dashboards with powerful tools for data analysis. Stay ahead of business objectives with a full library of customizable charts and tables, monitor key performance indicators, and gain at-a-glance trending insights.

Effortless Web-Based Deployment and Infinite Scalability

With PTI's solutions, instantly web-launch an unlimited number of zero-install, full runtime clients from a central server. With diverse architectures and an unlimited licensing model, Ignition seamlessly accommodates any implementation size, effortlessly scaling with your company's needs.